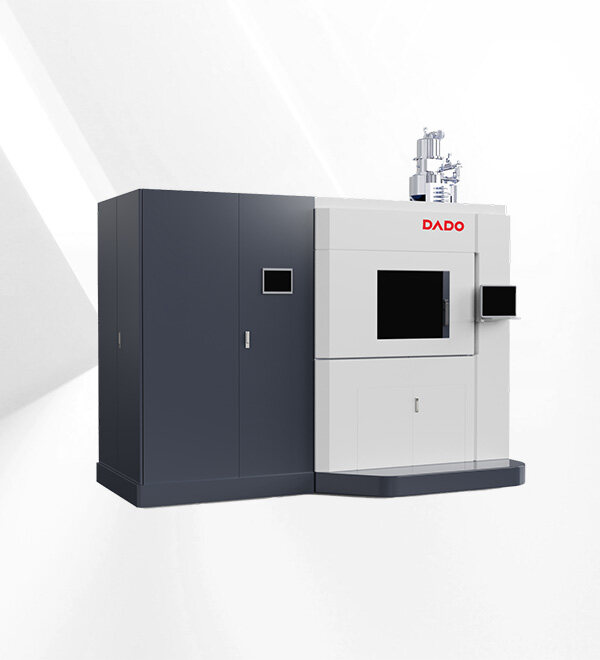

According to different printing materials and parts, scraper blades of different materials can be selected; two-way powder laying, 2 galvanometers;

humanized design, visualization and humanization of the operation interface; convenient operation and maintenance, double filtration system, good process safety;

high molding accuracy, self-designed light path system, excellent wind field design to ensure high molding accuracy and forming part performance;

wind field structure optimization design to ensure effective removal of smoke and dust, splash, and uniform printing of full-format parts;

self-developed process software optimizes scanning path to shorten processing time; multi-material and multi-process open system can configure process parameter packages of different materials;

system automatically records detailed processing process logs, part printing process layer number, part temperature, cabin pressure, The oxygen content, the position of the forming cylinder, the position of the material cylinder, the position of the powder laying truck, and the processing time are all recorded to ensure the high quality performance of the product.