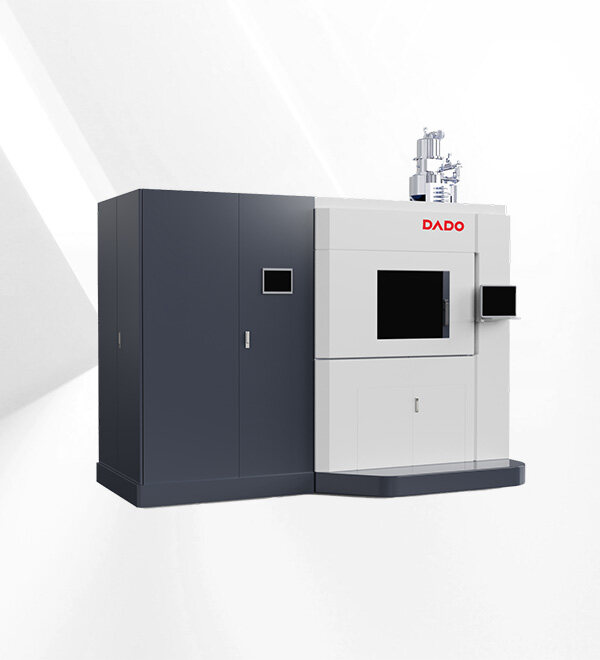

Laser cleaning technology, with its unique non-contact, efficient and environmentally friendly characteristics, has shown unparalleled advantages in the automotive parts industry. The technology uses high-energy laser beams to act directly on the surface of the workpiece, and precisely removes various impurities through photothermal and optical effects, which brings revolutionary changes to the manufacturing, assembly and maintenance process of automotive parts.

1. Efficient and accurate, improve production efficiency

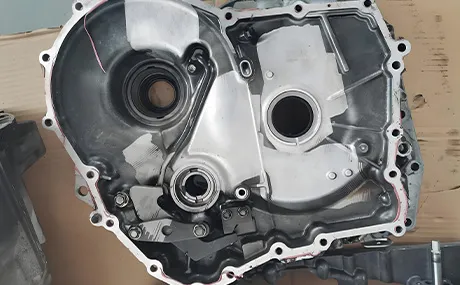

Engine parts cleaning: For the complex and precise parts inside the engine, the laser cleaning machine can quickly penetrate and peel off stubborn dirt such as oil stains and carbon deposits to ensure that the performance of the engine is not affected, and at the same time greatly shorten the cleaning time and improve the overall production efficiency.

Brake system cleaning: For key brake components such as brake discs and brake pads, laser cleaning technology can precisely control the laser beam, effectively remove tiny contaminants such as metal chips, avoid surface damage caused by traditional methods, and ensure the safety and stability of the braking system.

2. Environmental protection and energy saving, in line with the green production trend

Laser cleaning process does not require the use of chemical solvents or a lot of water resources, reducing environmental pollution and wastewater treatment costs. Its high-efficiency energy conversion rate also means lower energy consumption, in line with the requirements of modern industry for green and sustainable production.

3. Non-destructive cleaning to protect the integrity of the substrate

The non-contact characteristics of laser cleaning ensure that no mechanical stress or wear will be caused to auto parts during the cleaning process, effectively protecting the integrity and original performance of the substrate, and prolonging the service life of the parts.

4. Wide applicability to meet diverse needs

Body and external parts cleaning: The laser cleaning machine can completely remove various stains on the body surface, restore the gloss of the vehicle appearance, and improve consumer satisfaction.

Electrical contactor cleaning: For the tiny dust and oxides on the electrical contactor, the laser cleaning technology can accurately remove and ensure the stable operation of the electrical system.

Wheel hub and brake line cleaning: Quickly remove dust, asphalt and other stubborn stains on the wheel hub to restore its aesthetics; at the same time, effectively clean the inner wall of the brake line to ensure the smooth and safe transmission of braking power.

Car paint cleaning and scratch repair: Under the premise of protecting the car paint from damage, the laser cleaning machine can remove surface scratches and defects and improve the overall aesthetics of the body.

5. Automation and intelligence to improve production flexibility

Laser cleaning machine is easy to integrate into the automated production line to achieve intelligent control and improve the flexibility and response speed of the production line. At the same time, its precise parameter adjustment function makes the cleaning process more flexible and diverse to meet the cleaning needs of different parts.

sum up, the application of laser cleaning machines in the auto parts industry not only improves production efficiency and product quality, but also promotes the development of green production. With the continuous progress of technology and the further reduction of costs, laser cleaning machines will play a more important role in the future auto parts industry and promote the transformation and upgrading of the entire industry.