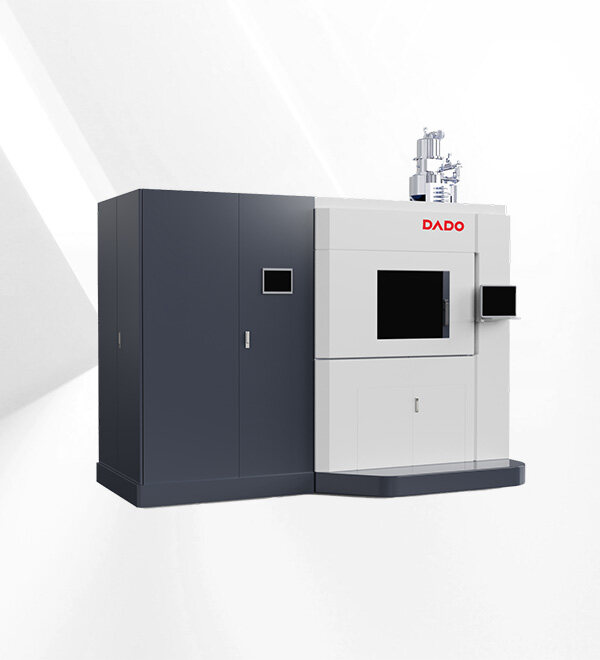

1. Efficient continuous laser cleaning: using a continuous laser, suitable for oil, oxide layer, weld cleaning, stains, rust spots, organic coatings and other surface treatment.

2. Excellent cleaning performance: cleaning speed, the maximum scanning width of 300mm, cleaning thickness up to 100μm, high efficiency to improve the operation efficiency.

3. Advanced laser cleaning principle: the use of laser high energy, high concentration of neutral irradiation of the workpiece, so that the surface attachments (dirt, oxide layer, rust spots, etc.) after absorbing laser energy, melting, gasification or expansion from the substrate surface, to achieve non-destructive cleaning.

4. Professional industry applications: widely used in high-speed rail, large ships, aerospace, hardware processing, power communications and other metal processing fields, to meet the needs of multi-scene cleaning.

5. Intelligent integrated design: integrated structure, equipped with special control system and software, can flexibly adjust parameters according to different cleaning needs, to achieve accurate and efficient operation.