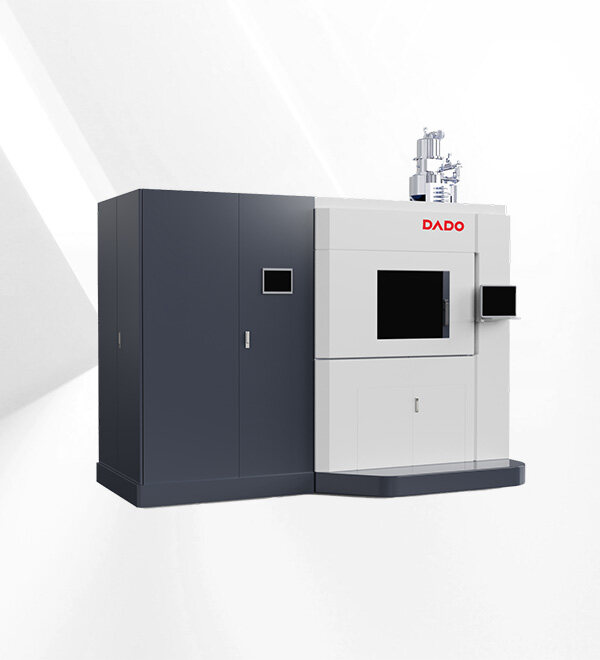

The three-dimensional five-axis fiber laser cutting machine adopts an elevated double-drive gantry structure, and the overall layout is stable and compact. The core beam is made of lightweight high-strength cast aluminum material, which significantly reduces the motion inertia while ensuring the rigidity of the structure, and realizes the perfect balance of high-speed displacement and precise control. Equipped with a five-axis linkage system, the equipment can realize any trajectory cutting of complex three-dimensional special-shaped parts. It can easily complete the rapid cutting, trimming and high-precision punching of curved parts, special-shaped pipes, automotive thermoforming parts, 3D metal forming parts, etc.

With its excellent processing efficiency, excellent cutting accuracy and excellent running stability, the equipment is widely used in high-end manufacturing fields such as automobile manufacturing, sheet metal processing, aerospace, home appliance manufacturing, etc., providing strong equipment support for enterprises to improve processing quality and production efficiency.

This three-dimensional five-axis fiber laser cutting machine is suitable for high-precision processing of automotive thermoforming parts, 3D metal forming parts, curved parts, special-shaped pipes, etc. It has the following core advantages:

Fully enclosed safety protection design: Equipped with multiple safety devices such as access control systems to ensure the safety and control of the production process;

high-end five-axis linkage numerical control system: As the “intelligent center” of the whole machine, it has both high flexibility, high precision and excellent stability, and can easily cope with complex three-dimensional trajectory processing;

elevated double-drive gantry bed: high rigidity and high strength, such as steel bars and iron bones, supporting high-speed and efficient cutting operations;

lightweight high-strength cast aluminum beam: Excellent dynamic performance, fast response, accurate positioning, and significantly improve processing efficiency.

The overall solution integrates high-end structural design and intelligent control technology to provide enterprises with efficient, accurate and stable 3D cutting solutions.