The principle of laser cleaning is to irradiate the surface with high-energy short pulses of laser, so that the dirt is heated and expanded and peeled off, while the substrate is almost unaffected. This method is especially suitable for applications such as precision parts, molds, welding pretreatment, etc. Compared with chemical cleaning, laser cleaning has no residue, no need to use solvents, and will not cause pollution to the environment. At the same time, compared with mechanical cleaning, laser cleaning will not damage the surface of the workpiece and avoid the impact of physical wear. Dongguan Yuan Intelligent Creation Technology Co., Ltd. uses advanced optical fiber transmission technology to ensure efficient and stable operation, providing intelligent cleaning solutions for enterprises.

- Building 2, Fenghui Plaza, No. 1, Hongyi Road, Nancheng Street, Dongguan City, Guangdong Province

- yuanzc@yuanzc.com

Portable pulse laser cleaning machine - air-cooled

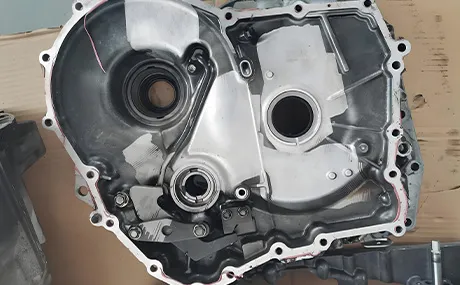

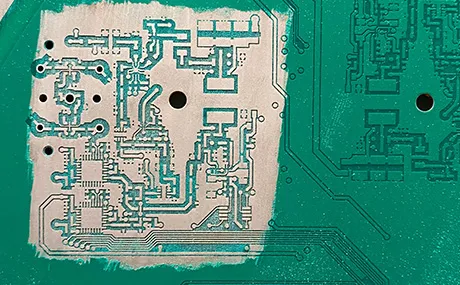

High efficiency precision laser mold cleaning machine

Portable pulse laser cleaning machine - air-cooled

High efficiency precision laser mold cleaning machine

- Home > Laser cleaning process analysis: efficient, safe and green