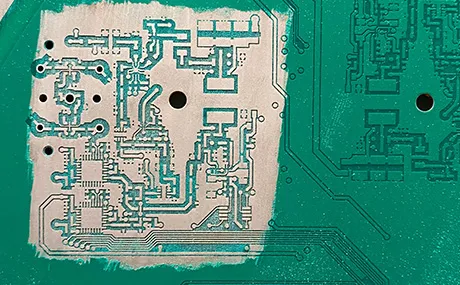

| Laser Cleaning |

Green and environmentally friendly, no chemical agents, no dust |

Safe, non-contact, optical transmission, avoids secondary damage |

High initial investment, low operating cost, no consumables |

Efficient, high-speed, suitable for multi-materials and contaminants, non-damaging |

Depends on equipment size, suitable for large to small scale cleaning tasks |

| Sandblasting |

Poor work environment, large dust and powder pollution |

High protection requirements, health risks |

Medium to high cost, high labor cost |

Efficient but polluting, may damage materials |

Affected by sand impact, not suitable for complex or precise work |

| Manual/Mechanical Polishing |

Pollutants cannot be collected |

Polishing tools may cause injury, hazardous |

Low equipment cost, high labor cost |

Less precise, reliant on human control, low efficiency |

Suitable for medium to large workpieces, not for fine or delicate tasks |

| Chemical Cleaning |

Pollutants cannot be collected |

High chemical risk, toxic, requires ventilation |

Medium to high operating cost |

High efficiency for certain applications, strict on cleaning requirements |

Suitable for standard workpieces, but not for residues or precision work |

| Wipe Cleaning |

Pollutants cannot be collected |

Toxic cleaning agents, absorption risks |

Low equipment cost, high water consumption |

Inefficient, not suitable for deep cleaning |

Suitable for small items, not suitable for precision work |

| Ultrasonic Cleaning |

Eco-Friendly |

Safe |

High equipment cost |

Suitable for small precision contamination, good cleaning effect |

Suitable for small workpieces, results depend on item quality and compatibility |